Search This Supplers Products:Stainless Steel ValvesBALL VALVESGATE VALVESGLOBE VALVESCHECK VALVESButterfly valves

What is Valve?

time2019/08/21

- Chances are there that you already know this. But there is no harm to refresh the memory.

Chances are there that you already know this. But there is no harm to refresh the memory.

Valve is a device that regulates, controls or directs the flow of a fluid by opening, closing, or partially obstructing fluid flow. Sound bit complicated? Ok, let me further simplified this. A valve is a mechanical device that controls the flow and pressure of fluid within a system or Process. So basically, it controls flow & pressure.

In piping following types of valves are used depending on the requirements. The cost of Valve in the piping system is up to 20 to 30% of the overall piping cost. And the cost of a given type and size of the valve can vary 100%. It means that if you choose ball valve over butterfly valve for the same function. It can cost you more. So, the selection of valves is essential to the economics, as well as operation, of the process plants.

§Gate Valve

§Globe Valve

§Check Valve

§Plug valve

§Ball Valve

§Butterfly Valve

§Needle Valve

§Pinch Valve

§Pressure Relief Valve

Gate valve is the most common type of valve in any process plant. It is a linear motion valve used to start or stop fluid flow. In service, these valves are either in fully open or fully closed position. Gate valves are used in almost all fluid services such as air, fuel gas, feedwater, steam, lube oil, hydrocarbon, and all most any services. Gate valve provides good shutoff.

Globe Valve

Globe valve is used to stop, start, and regulate the fluid flow. Globe Valves are used in the systems where flow control is required and leak tightness is also necessary. Globe valve provides better shut off as compared to gate valve and it is costlier than gate valve.

Check Valve

The check valve prevents backflow in the piping system. The pressure of the fluid passing through a pipeline opens the valve, while any reversal of flow will close the valve.

Plug valve

Plug valve is Quarter-turn rotary motion Valve that uses a tapered or cylindrical plug to stop or start the flow. The disk is in plug shape, which has a passage to pass the flow. Plug valve used as on-off stop valves and capable of providing bubble tight shutoff. Plug valve can be used in vacuum to high-pressure & temperature applications

Ball Valve

A Ball valve is a quarter-turn rotary motion valve that uses a ball-shaped disk to stop or start the flow. Most ball valves are of the quick-acting type, which requires a 90° turn of the valve handle to operate the valve. The ball valve is Smaller and lighter than a gate valve of same size and rating.

Butterfly Valve

A Butterfly valve is a quarter-turn rotary motion valve, that is used to stop, regulate, and start the flow. Butterfly valve has a short circular body. Butterfly Valve is suitable for large valve applications due to Compact, lightweight design that requires considerably less space, as compared to other valves.

Needle Valve

Needle valves are similar to a globe valve in design with the biggest difference is the sharp needle like a disk. Needle valves are designed to give very accurate control of flow in small diameter piping systems. They get their name from their sharp-pointed conical disc and matching seat.

Pinch Valve

The pinch valve is also known as clamp valve. It is a linear motion valve. Used to start, regulate, and stop fluid flow. It uses a rubber tube, also known as a pinch tube and a pinch mechanism to control the fluid. Pinch Valve is ideally suited for the handling of slurries, liquids with large amounts of suspended solids, and systems that convey solid material pneumatically.

Pressure Relief Valve

A pressure Relief valve or pressure safety valve are used to protect equipment or piping system during an overpressure event or in the event of vacuum. This valve releases the pressure or vacuum at pre-defined set pressure.

Valves Functions

Valve serve a various function within the piping system. Such as

§Stopping and starting a fluid flow. Depending on whether a valve is open or closed, it let pass the process fluid or halt the fluid.

§Throttling the fluid flow. Some of the valves let you throttle the fluid depending open % of total opening. Lesser the opening higher the throttling and otherwise.

§Controlling the direction of a fluid flow. Multiport valve lets you decide the way fluid will go.

§Regulating a flow or pressure within the piping system. Some of the automatic control valves maintain the flow and pressure within the system by adjusting opening and closing.

§Relieve pressure or vacuum from the piping system and equipment. Pressure and vacuum relief valve safeguard the process system from overpressure and during vacuum condition.

Different types of valves serve these functions. These valves can be classified or categorized based on;

§Function

§End connection

§How it operates

§Types of Actuator it used.

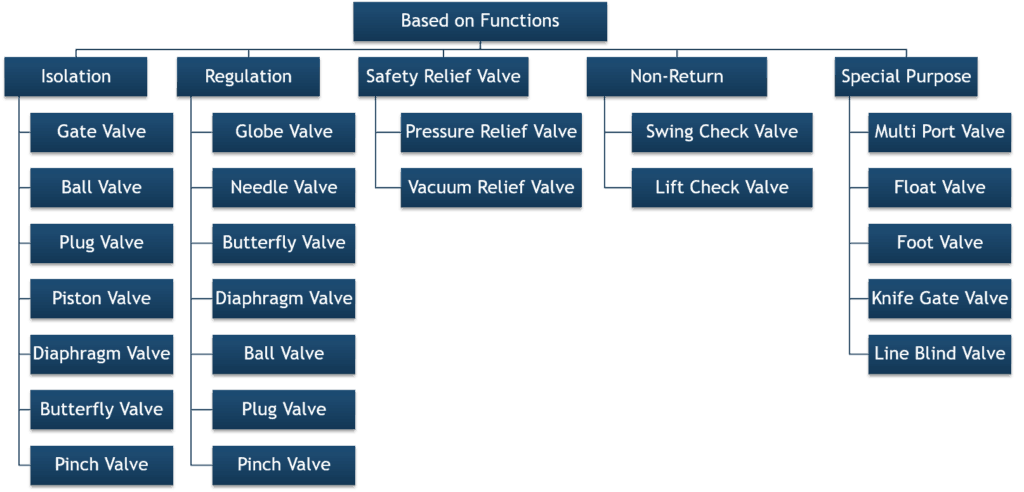

In the above chart, you can see the types of valves and their function.

Isolation valve isolates or cuts the supply of fluid when needed. Gate, ball, plug, piston, diaphragm, butterfly and pinch valve falls under this category.

A control valve that regulates the flow of fluid falls in the regulation category. Globe, needle, butterfly, diaphragm, ball, plug, and pinch valve are used as a control valve. You can see that; some valves serve dual purposes such as globe and ball valve can be used as an isolation as well as a control valve.

Pressure and vacuum relief valve used to prevent overpressure and vacuum with the system that can damage the piping and equipment. Non-return valve such as swing and lift check valve prevents backflow within the system. Whereas, some valves are designed to serve a special purpose. Such as multiport, knife, and line blind valve.