Search This Supplers Products:Stainless Steel ValvesBALL VALVESGATE VALVESGLOBE VALVESCHECK VALVESButterfly valves

Forged Steel Swing type/Lift type Check Valve

- group name

- FORGED STEEL VALVE

- Min Order

- 1 piece

- brand name

- RST/OEM

- Nearest port for product export

- SHANGHAI, NINGBO

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, Westem Union, Cash

- update time

- Mon, 28 Sep 2020 16:17:08 GMT

Paramtents

Size 1/2''~2''

Material F304/F316/F304L/F316L/F11/F22/F51/F91,etc.

Pressure 150LB~2500LB

Type Swing type & Lift type

Ends NPT/BSPP/BSPT/SW

Packging & Delivery

-

Min Order1 piece

Briefing

stainless steel check valve, forged steel check valve, swing type ss check valveSwing type/Lift type Check Valve

Detailed

Forged Steel Swing type/Lift type Check Valve

Features:

1. 150LB~2500LB option

2. Stainless steel disc

3. Screwed cap

4. Bolted bonnet or welded bonnet or pressure seal bonnet

5. Non return disc

6. Spiral-wound gasket

7. Swing type, lift type available

8. Threaded or socket weld ends

Design construction:

1. ASME B16.34 - BS 5352

2. Testing according to API 598

3. Socket Weld Ends to ASME B16.11

4. Screwed Ends (NPT) to ASME B1.20.1

5. Butt Welding Ends to ASME B16.25

Specification:

|

Brand |

RST

|

||

|

1. Material

|

F304/316/304L/316L ( CF8/CF8M/CF3/CF3M), A105,F11,F22,F51,LF2 etc.

|

||

|

2.Size

|

1/2’’~4’’

|

||

|

3.Certificates

|

ISO9001 & CE, TS

|

||

4.Port | Reduce Port | ||

5.Working Pressure | 150LB~2500LB/PN16~PN160 | ||

6.Connection Ends | NPT/BSPP/BSPT/BW/SW, etc. | ||

7.Working Temp | -20~425℃, or according to customer requirements for different industry. | ||

8.Suitable Medium | Water, Natural Gas, Oil and some corrosive liquid | ||

9. Operated | Handwheel Operated, Gear, Actuators | ||

Valve Test | 100% quality tested before delivery | ||

Shipment | |||

Delivery Time | 15~30 Days | ||

Package | Standard Exporting Plywood Case | ||

Shipping Port | Ningbo/Shanghai, China | ||

Shipping Terms | Exw, FOB, CFR, CIF, etc. | ||

Payment Terms | T/T, B/L, D/A, D/P, etc. | ||

30% prepayment, 70% balance paid before shipping or against copy of BL | |||

Valve Guarantee | 18 month after shipments | ||

Valve Sample | Sample available by RST VALVE | ||

MOQ | 1 SET |

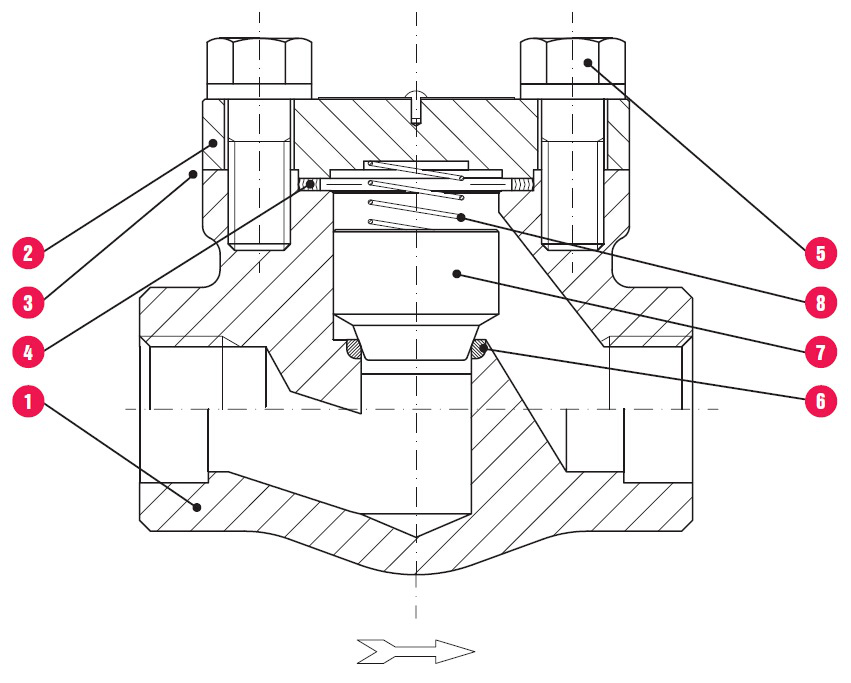

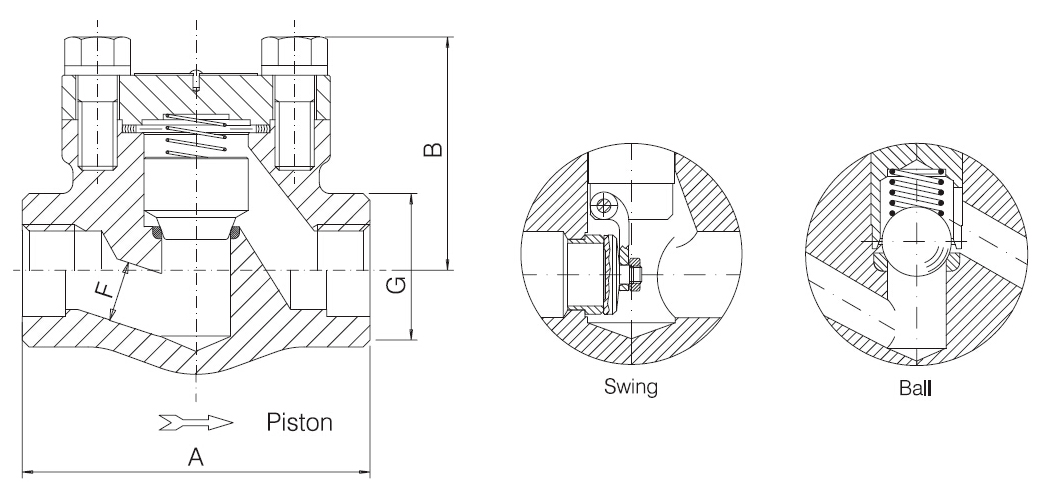

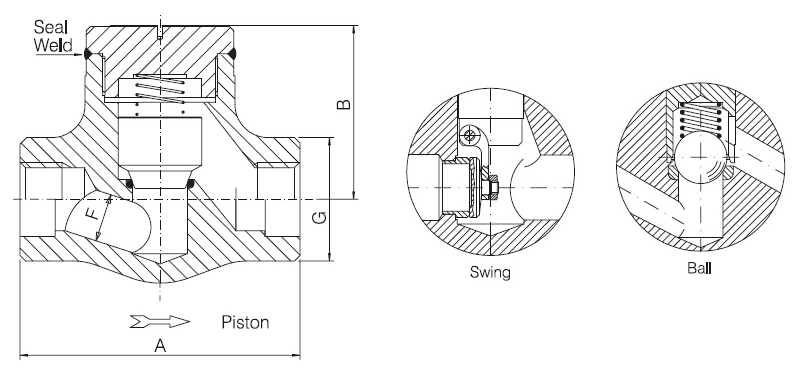

Constructions:

1. BODY. The body is forged steel and designed to the basic dimensional requirements of the applicable specifications such as API 602 and ASME B16.34. The body is available in both the full or conventional port design. It is also available in either T-Pattern or Y-Pattern configurations.

2. COVER. The cover is forged steel and designed to the basic dimensional requirements of the applicable specifications such as API 602 and ASME B16.34.

3. BODY-COVER JOINT. Two different cover joint designs are available. These are either the bolted cover or the threaded and seal welded type.

4. GASKET. The bolted cover joint design valve uses a contained, controlled compression, spiral wound type gasket.

5. COVER BOLTING. The cover bolting is manufactured of alloy steel in accordance with the requirements of the applicable specifications such as API 602 and ASME B16.34.

6. SEAT. The body seat for the piston and ball check valves is an integral weld overlay and is part of the valve trim. The swing check valve is supplied with a separate seat ring which is pressed into the valve body and wedged into place, forming a seal with the body.

7. PISTON, BALL OR DISC. The piston, ball or disc is forged steel and is part of the valve trim. The seating surface of the piston and ball check is of the tapered or plug type design. The seating surface of the swing check is of the flat seat design.

8. SPRING. The spring is optional and supplied only upon request.

Thread/Welding ends Type

Applications:

1. Chemical Industry

2.Petro-chemical Industry

3. Plant Construction

4. Power Plant Engineer

5. Paper & Pump Industry

6. Mining

7. Gas Utilities

8. Environment Technologies

9. Steam Generation

10. Drink water

11. Sewage water industry